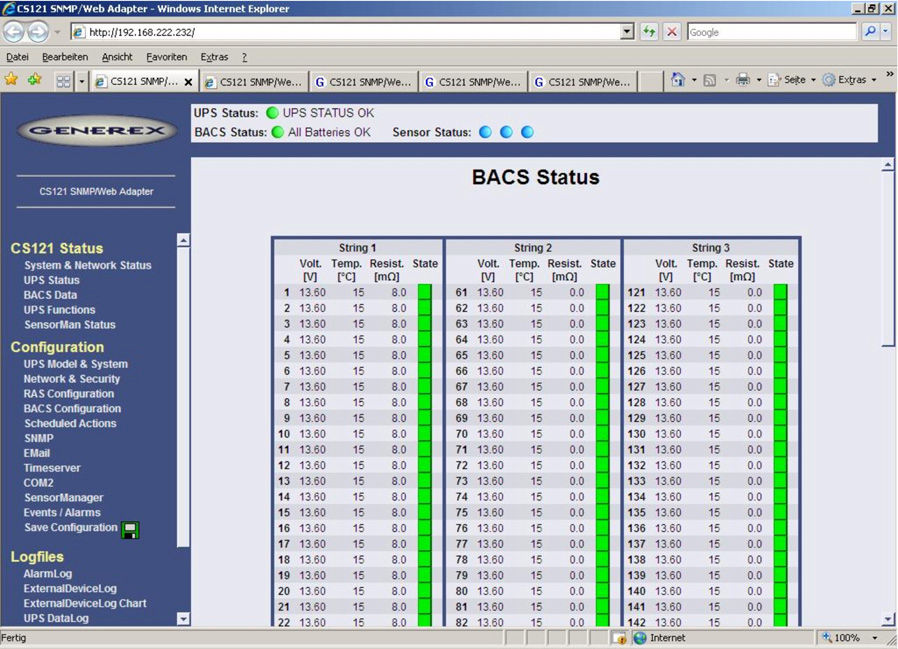

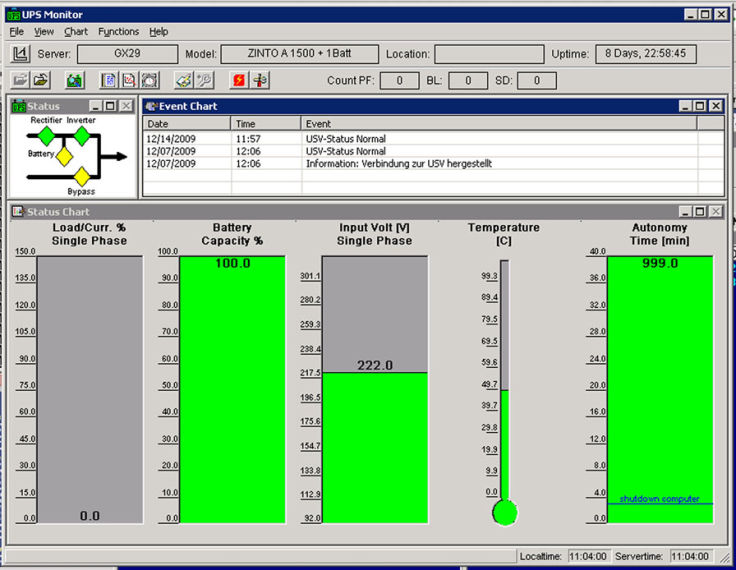

The Generex Battery Analysis & Care System

More than 700,000 BACS modules since market launch in 2004

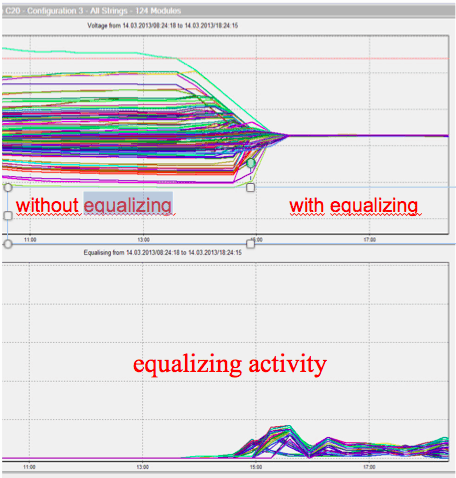

Advanced warning of potential battery problems!

Helps to extend the life of your battery by up to 30%!